1. the slotted sleeves

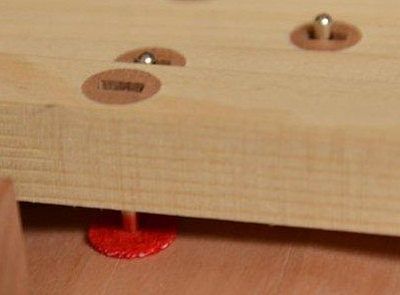

While the key is being played, it rotates around the pin that is driven into the balance beam. There is a hole on the bottom that is exactly the same diameter as the beam pin. A 10mm hole is drilled from above towards this small hole, only so far that the small hole is only 2-3mm deep. This small oblong hole sleeve is now glued into the top side. Of course, the slot must be aligned along the key in the direction of movement. This way the key is well guided, but it is not stuck in the wood. The rear guide is first drilled out completely with 10mm and then also provided with an oblong hole sleeve.