1. large formats:

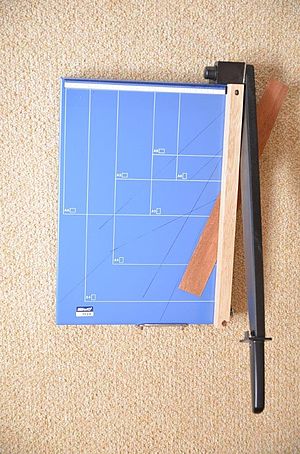

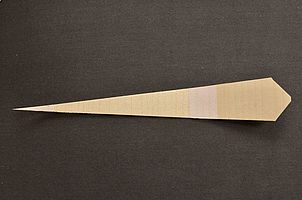

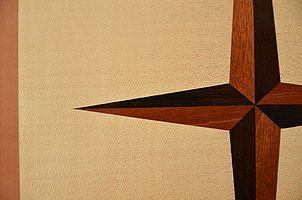

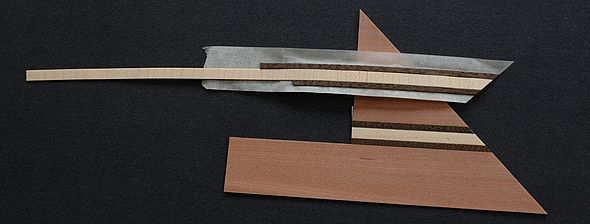

A tip for strip cutting and cutting large formats without a circular saw:Two planks for the production of decorative stripsTension the veneer sheet between two planks with clamps. One board serves as a cutting board, the second one as a ruler. The desired veneer width is displayed under the ruler. The strips may only be pre-cut during the first pull, thus reducing tearing. These planks can also be used as an aid for gluing decorative strips. 3 mm of the adhesive veneer tape are stretched with the glue side upwards, under the ruler (upper board). The ruler serves as a stop, so we get straight decorative strips. In the background of the photo you can see a wooden scantlings lying on the decorative strip. When the thin strips of veneer come into contact with water, you want to roll yourself. The cantle is used to counteract this.